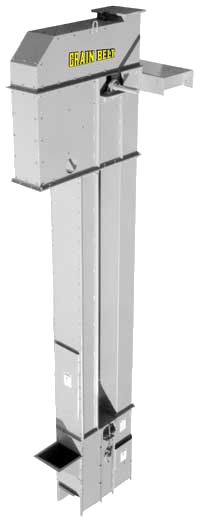

Bucket Elevators

We offer quality and dependability, backed by over 47 years of experience in the grain handling industry.

Grain Belt Bucket Elevators have been designed and engineered for handling your bulk material.

Bucket Elevator Brochure

Industrial Duty Bucket Elevators

Grain Belt Standard Features

- High-speed one-piece elevator buckets (metal or plastic).

- Solid steel head and boot pulleys.

- Head pulley crowned, lagged and keyed.

- 12 ga. dust and weatherproofed head and vent cap.

- 10 ga. steel boot with cleanout slides and two pockets.

- 14 ga. welded steel leg sections (Two piece construction).

- Full access inspection section.

- Jig built for easy field erection.

- Two boot pockets; feeds buckets uniformly up or down side.

- P.V.C. belt pre-punched.

- Boot shaft bearings covered.

- Long lasting, high quality bearings.

- Adjustable throat plate.

Grain Belt Optional Features

- Work platforms

- Distributor platforms

- Ladder

- Safety cage

- Rest platforms

- Explosion vents

- Wing type boot pulley

- Available in mild steel, stainless steel, or galvanized

4000 to 8000 bph Stock Industrial Bucket Elevator Specifications

Head

12 ga., three piece construction, 1/4" expanded metal backed urethane lined front crown and discharge, 30" x 15" keyed and lagged pulley, 12" sq. inspection opening, dust seals on head shaft, adjustable throat plate.

Boot

10 ga., bolted construction, 12" travel take-ups, two loading pockets, 2 7/16" shaft, 30" x 15" pulley, 8" sq. inspection opening, dust covers over bearings, removable clean out slides.

Trunking

14 ga., two piece design, 13" x 18" cross section, inspection section with 10' bolt on side and two 18" x 30" inspection doors.

General

14" wide PVC belting, 13" x 6" or 13" x 7" Grain Belt plastic or steel CC style elevator cups.

Heavy Duty Bucket Elevators

Grain Belt Standard Features

- High-speed one-piece elevator buckets (metal or plastic).

- Quality ball bearings used throughout

- Head pulley crowned, lagged and keyed.

- 12 ga. dust and weatherproofed head and vent cap.

- 12 ga. bolt together boot with cleanout slides and one pocket.

- 14 ga. welded steel leg sections (Two-piece construction).

- Jig built for easy field erection.

- Solid steel head and boot pulleys.

- Head pulley crowned, lagged and keyed.

- Adjustable throat plate.

- P.V.C. belt pre-punched.

- Full access inspection section.

Grain Belt Optional Features

- Work platforms

- Distributor platforms

- Ladder

- Safety cage

- Rest platforms

- Explosion vents

- Wing type boot pulley

- Available in mild steel, stainless steel, or galvanized

500 to 3500 bph Stock Heavy-Duty Bucket Elevator Specifications

Head

12 ga., two piece construction, 1/4" expanded metal backed urethane lined front crown and discharge, 16" x 11" keyed and lagged pulley, 12" sq. & 10" sq. inspection openings, dust seals on head shaft, adjustable throat plate.

Boot

12 ga., bolted construction, 9" travel take-ups, one loading pocket, 1 15/16" shaft, 16" x 11" pulley, 8" sq. inspection opening, removable clean out slides.

Trunking

Standard trunking available in 20', 10' and 5' lengths. 14 ga., two piece design, 10" x 13" cross section, 1 1/4" angle flanges, inspection section with 10' bolt on side and two 11" x 30" inspection doors.

General

10" wide PVC belting, 9" x 5" and 9" x 6" Grain Belt steel or plastic CC style elevator cups.

8000 to 15000 Stock Industrial Duty Bucket Elevators

Grain Belt Standard Features

- High-speed one-piece elevator buckets (metal or plastic).

- Solid steel head and boot pulleys.

- Head pulley crowned, lagged and keyed.

- 10 ga. dust and weatherproofed head and vent cap.

- 7 ga. bolted steel boot with cleanout slides and two pockets.

- 12 ga. welded steel leg sections (Two piece construction).

- Full access inspection section.

- Jig built for easy field erection.

- Two boot pockets; feeds buckets uniformly up or down side.

- P.V.C. belt pre-punched.

- Dust seals on the boot shaft.

- Long lasting, high quality bearings.

- Adjustable throat plate.

Grain Belt Optional Features

- Work platforms

- Distributor platforms

- Ladder

- Safety cage

- Rest platforms

- Explosion vents

- Wing type boot pulley

- Available in mild steel, stainless steel, or galvanized

8000 to 15000 bph Stock Industrial Duty Bucket Elevator Specifications

Head

10 ga., three piece construction, 1/4" expanded metal backed urethane lined front crown and discharge, 42" x 19" keyed and lagged pulley, 12" sq. inspection opening, dust seals on head shaft, adjustable throat plate.

Boot

7 ga., bolted construction, 12" travel take-ups, two loading pockets, 2 15/16" shaft with Pillow Block Bearings, 42" x 19" pulley, 8" sq. inspection opening, dust seals on the boot shaft, removable clean out slides.

Trunking

Standard trunking available in 20', 10' and 5' lengths. 12 ga., two piece design, 15" x 22" cross section, inspection section with 10' bolt on side and two 22" x 30" inspection doors.

General

18" wide PVC belting, 16" x 7" or 16" x 8" Grain Belt plastic or steel CC style elevator cups.

14000 to 20000 Industrial Duty Bucket Elevators

Grain Belt Standard Features

- High-speed one-piece elevator buckets (metal or plastic).

- Solid steel head and boot pulleys.

- Head pulley crowned, lagged and keyed.

- 10 ga. dust and weatherproofed head and vent cap.

- 7 ga. bolted steel boot with cleanout slides and two pockets.

- 12 ga. welded steel leg sections (Two piece construction).

- Full access inspection section.

- Jig built for easy field erection.

- Two boot pockets; feeds buckets uniformly up or down side.

- P.V.C. belt pre-punched.

- Dust seals on the boot shaft.

- Long lasting, high quality bearings.

- Adjustable throat plate.

Grain Belt Optional Features

- Work platforms

- Distributor platforms

- Ladder

- Safety cage

- Rest platforms

- Explosion vents

- Wing type boot pulley

- Available in mild steel, stainless steel, or galvanized

14000 to 20000 bph Industrial duty Bucket Elevator Specifications

Head

10 ga., three piece construction, 1/4" expanded metal backed urethane lined front crown and discharge, 42" x 23" keyed and lagged pulley, 12" sq. inspection opening, dust seals on head shaft, adjustable throat plate.

Boot

7 ga., bolted construction, 12" travel take-ups, two loading pockets, 3 15/16" shaft with Pillow Block Bearings, 42" x 23" pulley, 8" sq. inspection opening, dust seals on the boot shaft, removable clean out slides.

Trunking

Standard trunking available in 20', 10' and 5' lengths. 12 ga., two piece design, 15" x 26" cross section, inspection section with 10' bolt on side and two 26" x 30" inspection doors.

General

22" wide PVC belting, 20" x 8" plastic or steel CC style elevator cups.